Peanut Shelling Machine Principle

Peanut Shelling Machine This Peanut Shelling Machine has a compact structure, easy operation, and reliable performance. It is used to shell peanuts; can separate shells and kernels with high efficiency and almost without damage to the kernel; the shelling rate can be ≥95%, the breaking rate is≤5%. Industrial Hemp Seed Shelling Machine

Diesel Fuel Peanut Sheller Groundnut Shelling Machine Earthnut Dehuller Hulling Machine China

.more #peanut #peanutsheller Website: https://www.peanuts-machine.com/product/groundnut-sheller/Email: [email protected]: +86 19139754781Peanut shel.

HYBH800C Peanut shelling machine, Peanut shelling machine

Model: KMBK-400;Capacity: 400-600KG/H. Groundnut seed sheller is a professional equipment for peanut shucking, the machine set peanut shucking, shell kernel separation in one, with simple structure, easy to operate, low power consumption, low noise and so on.

SemiAutomatic Painted Peanut Shelling Machine, 2 HP, Single Phase, Rs 8999 /piece ID 22422730730

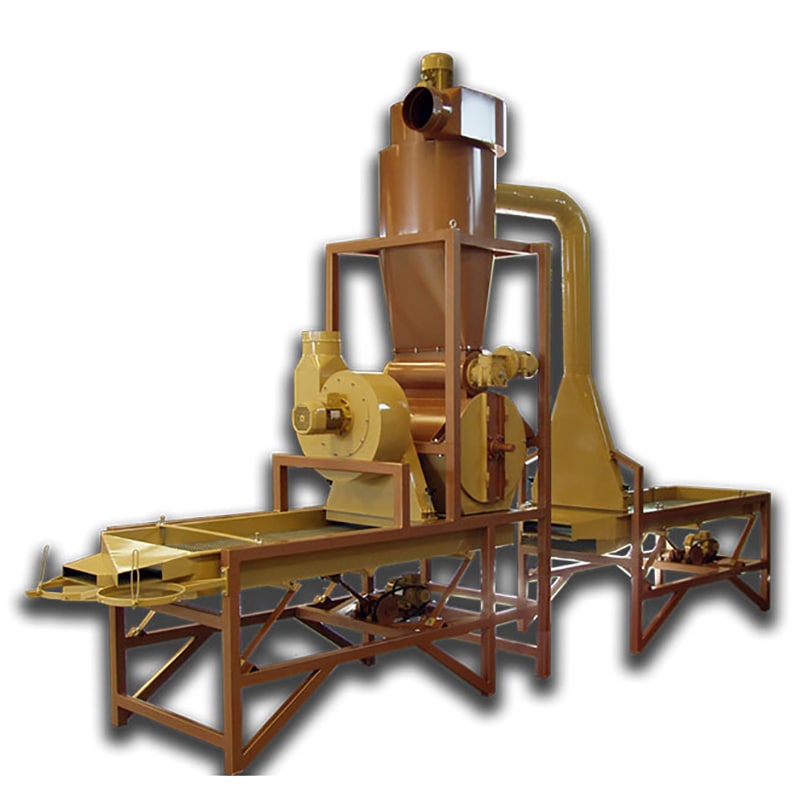

Four Types of Combined Groundnut Shelling and Cleaning Machine. As a professional manufacturer and producer of agricultural equipment, we offer many types of peanut shelling and cleaning machine, 6BHX-1500, 6BHX-3500, 6BHX-16000 and 6BHX-20000, our combiend peanut sheller is a machine that removes the stones and cleans the peanuts before shelling them, it's very efficient.

Supply Peanut Shelling/Dehulling Machine, Peanut Sheller/Decorticator/Dehuller

A peanut shelling machine has been designed, which imitated manual peanut peeling method. The mechanical structure of the peanut shelling machine consists of a frame, a feeding mechanism, a pneumatic gripper and peanut shelling positioning mechanism. The control system is composed of a MCU, LCD 12864 liquid-crystal display, and keys.

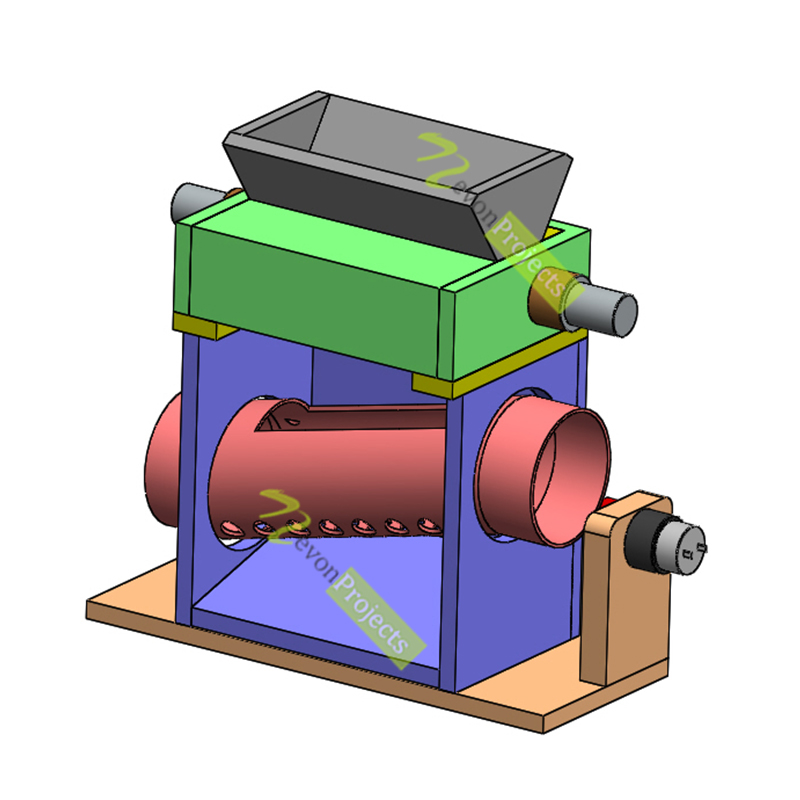

Design and Fabrication of Mini Groundnut & Peanut Shelling Machine

According to the shelling principle of the scraper peanut shelling machine, it can be known that the peanuts pass through the collecting hopper, shelling box, screen grid, lower box outlet, sorting port, and peanut kernel collecting bucket in order from top to bottom, so the design The basis for the overall structure of the sheller comes out.

Peanut Shell Machine, Good Peanut Shelling Equipment for Investment

The LMC Peanut Sheller cylinder is designed to shell peanuts and is an integral part of the shelling system with high efficiency, high capacity and minimum split creation. The vast majority of the United States commercial peanut crop is shelled on the LMC Peanut Sheller.

Full Automatic Combined Peanut Sheller with Cleaning Equipment China Peanut Shelling Machine

working process of the sheller Automatic peanut sheller machine design Groundnut sheller is composed of a frame, double drums, rotor, fan, vibrating screen, and single-phase motor. Therefore, the machine has a shelling structure, screening structure, wind selection structure, and wind feeding structure. Machine parameters

Peanut Sheller/peanuts Shelling Machine Peanut Peeling Machine Buy High Quality Peanut Sheller

Welcome to select and purchase. KMBK-200 Peanut Shelling Machine Capacity: 200KG/H; The small peanut shelling machine can adapt to different varieties of peanut shelling, due to its small size, easy operation. KMBK-70 Peanut Shelling Machine Capacity: 500-700KG/H;

Methods of application and precautions Factory direct small peanut shelling machine

Peanut Shellers Used to shell peanuts with high efficiency, high capacity and minimum split creation. Read More Sizing Shakers Used to separate dry, flowable products, like peanuts, by specific size. Read More Destoners The LMC Destoner has a reputation for being the most reliable, user-friendly, and efficient destoner available. Read More

Peanut shelling cracking machine groundnut sheller

Shelling by Shearing: Peanut pods are subjected to the shearing force of a relatively moving knife plate between the fixed knife holder and the drum.The shell is cut and opened to separate the shell from the kernel. Its typical equipment is a blade shelling machine with blade drum and blade base as its main working parts.

Peanut Shelling machine Food machinery supplier

About us More. Romiter Machinery Co., Ltd. is a market leading manufacturer of Onion Processing Machine with 10 years experience. Our factory is company, located at Middle China. Romiter has an excellent technical support team, including highly experienced machinists and service technicians. All our machines equip with reliable brand components.

Video New Rongyao Factory peanut shelling pulps sheller machine from Peanut pulperin Food

KMBK-4500B type peanut sheller and cleaning machine is a new generation of multifunctional speed-regulating. Our company is specialized in the production of all kinds of peanut shelling machine and its ancillary equipment. Welcome all of our customers to come and visit our company, the staff of our company will serve you wholeheartedly.

The Invention of the Peanut Sheller Has Brought Great Benefit to Farmers

1. Small peanut shelling machine can realize multiple function of peanut shelling, air delivery and separation, it is widely used for and home and commercial application. 2. High shelling rate, more than 97%. 3. Well-designed air dryer can blow out the peanut shell, and help improve the final product clean. 4.

Peanut Cracking Shelling Machine ADR IMPEX EOOD

The peanut shelling machine is composed of frame, air fan, rotors, single-phase motor, two sizes screens, feeding hopper, vibration sieving screen, V-belt wheel and transmission V-belt. After the machine started, the peanuts are put into the hopper in a quantitative, uniform and continuous manner. The peanut shells are broken under the constant.

Peanut Sheller shelling machine / groundnut sheller factory

The Universal Nut sheller in Uganda, 2005. The universal nut sheller (UNS; formerly called the Malian peanut sheller) is a simple hand-operated machine capable of shelling up to 57 kilograms (126 lb) of raw, sun-dried peanuts per hour.. It requires less than $10 USD in materials to make, and is made of concrete poured into two simple fibreglass molds, some metal parts, one wrench, and any.